Alberta Flooding: Local Knowledge and Intelligent Design of Culvert Structures Yield Improved Efficiency and Durability

By Ron Prychitko, P. ENG.

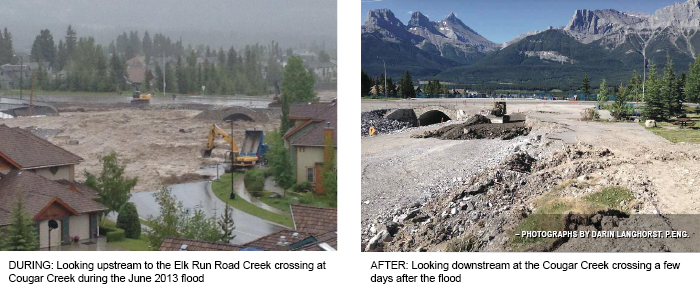

In late June of this year, record flooding in Alberta washed out the Trans-Canada Highway where it crossed Cougar Creek, in Canmore. Reports of up to 300 mm of rain in the area in little more than 24 hours combined with the spring snowmelt from the mountains coalesced to create a raging torrent of destruction.

The result: a perfect storm.

Cougar Creek, typically dry throughout 90 percent of the year and contained within banks some 50 metres in width, was suddenly and violently transformed into a vicious and abrasive torrent of rushing water, rocks, boulders, trees and debris, in places swelling to 150 metres in width. As the storm raged, Cougar Creek was hastily carving out a new path through the Bow Valley. And it was, literally, unstoppable.

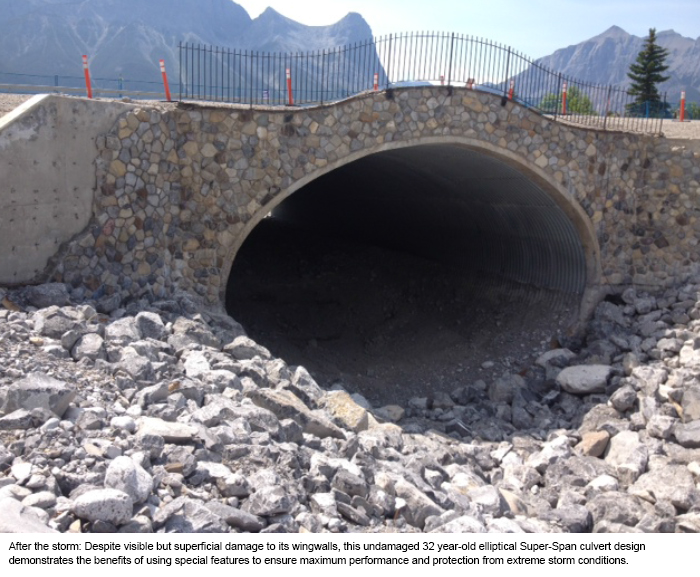

With the Trans-Canada Highway and CPR mainline closed, Canmore’s only remaining east-west route was Elk Run Boulevard, located just upstream from the Trans-Canada crossing. The Cougar Creek buried steel structure at Elk Run, installed in 1982, is a horizontal ellipse, Super-Span culvert design, 9.5 metre span by 6.45 metre rise. It features corrugated steel plates 4.0 mm in thickness, with structural plate ribs at 1.8 m centers, as well as concrete thrust beams. Miraculously, due to the special features incorporated into the structure by designer Jens Madsen, along with the co-ordinated diligence and hard work of emergency personnel, engineers and local contractors, ‘the little culvert that could’ continued to function and remained structurally sound, even as the aggressive torrent began to take out road embankment fill beside the headwalls and threatened to crest the road.

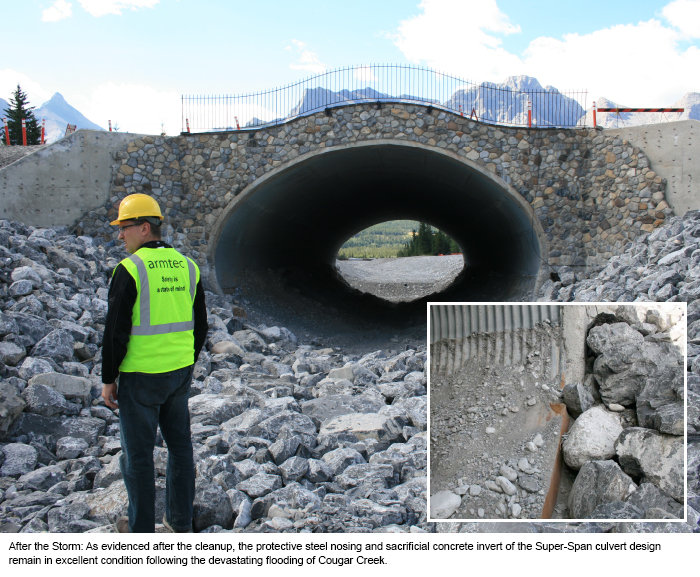

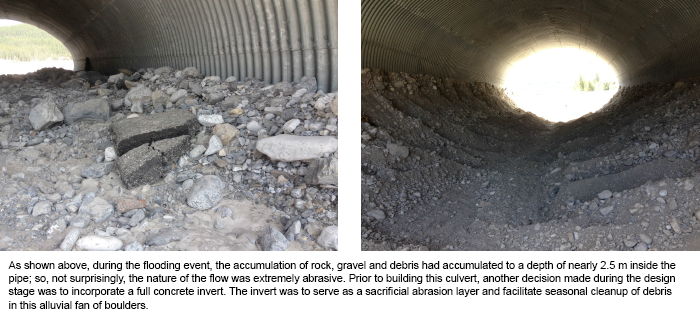

The Super-Span® corrugated steel structure utilizes Multi-Plate (SPCSP) and, with some minor modifications, achieves an effective long-span soil/steel structure. Importantly, during the planning stages for this culvert installation, some strategic thinking and prudent design decisions led to the specification and incorporation of some unique special features at the site, including a protective steel plate nosing and concrete paved invert, collars, cut-off walls, headwalls and wingwalls.

And, although the culvert structure received help, the special features incorporated at the design stage proved to be very effective in doing their job for the duration of the flood. Trackhoes and dump trucks were deployed to replace the diminishing road embankment fill around the upstream section of the crossing, to prevent the entire crossing from washing out. This emergency work continued diligently over the next several days and succeeded in preventing a catastrophic breach. When the deluge finally ended, water levels quickly subsided, and in about a week the creek was again dry.

As evidenced in the photos below, a subsequent inspection by CSPI representatives in July revealed that, despite the beating dished out by Mother Nature, this 32 year old corrugated steel culvert structure remained in excellent condition. The headwalls, wingwalls and cut-off walls had effectively directed flows through the culvert to help protect the road. Moreover, a protective steel plate ring at the entrance and sacrificial paved concrete invert running throughout the length of the structure further assisted the culvert in fulfilling its defensive role.

“The fact that this structure continued to work throughout the flooding is a testament to the importance of applying local knowledge during the design stage, to identify and incorporate whatever relevant special features can increase the performance and protection efficiencies of a culvert,” says Dave Penny, Executive Director of the Corrugated Steel Pipe Institute. “In this case, the local designers were intimately versed in the infrequent but extreme flashiness of Cougar Creek, so, at the planning stages of the installation, they were fully cognizant that a headwall and wingwalls would enhance the structure’s ability to direct heavy flows of water and debris through the culvert during rainfalls and runoffs. That, in turn, would facilitate maximum throughput of the pipe, while optimizing protection of the road and the embankment,” he adds.

After the flood, at a TAC/ATC Structures Standing Committee meeting, Des Williamson, Chief Bridge Engineer for Alberta Transportation, reviewed the files of many bridges that were destroyed. He was also able to share with Canada’s bridge engineers the story of how this 32 year old SPCSP culvert came through the Cougar Creek flood with flying colours.

For information on planning and designing corrugated steel structures, contact the Corrugated Steel Pipe Institute (CSPI): Ph 519.650.8080, Fax: 519.650.8081, email: info@cspi.ca